China Regenerative Thermal Oxidizer: A Comprehensive Guide to Efficient Air Pollution Control

Introduction

China, one of the world’s largest industrial powers, has been making significant strides in environmental protection and air quality improvement. As the country continues to grow, the need for effective air pollution control technologies becomes increasingly important. One such technology that has gained widespread recognition and adoption is the China Regenerative Thermal Oxidizer (RTO). This article provides a comprehensive overview of RTOs in China, their working principles, advantages, applications, and the regulatory landscape.

What is a Regenerative Thermal Oxidizer (RTO)?

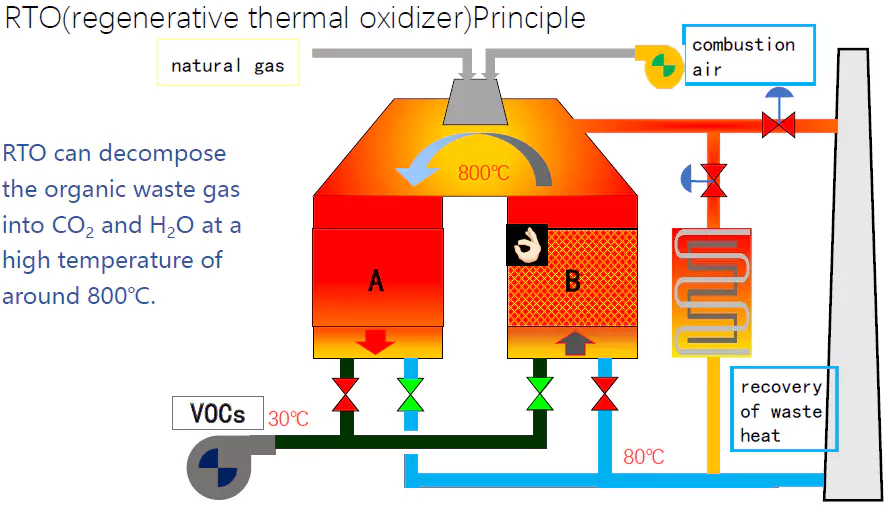

A Regenerative Thermal Oxidizer (RTO) is an advanced air pollution control system designed to destroy Volatile Organic Compounds (VOCs), Hazardous Air Pollutants (HAPs), and other harmful emissions. The RTO operates by heating the incoming exhaust gases to high temperatures, typically between 800°C and 900°C, where the pollutants are oxidized into harmless carbon dioxide and water vapor. The key feature of an RTO is its ability to recover and reuse heat, making it highly energy-efficient.

Working Principles of RTO

- Multi-Bed Design: RTOs use multiple beds of ceramic media to store and release heat. The process involves alternating the flow of hot and cold gases through these beds.

- Heat Recovery: As the hot, clean gas exits the combustion chamber, it passes through a bed of ceramic media, transferring its heat to the media. When the gas flow direction is switched, the incoming cold, contaminated gas is preheated by the hot ceramic media.

- High-Temperature Oxidation: The preheated gas then enters the combustion chamber, where it is further heated to the required temperature for complete oxidation.

- Automated Control: Advanced Programmable Logic Controllers (PLCs) manage the switching of gas flow and ensure optimal performance and safety.

Advantages of RTOs

- High Efficiency: RTOs can achieve up to 99% VOC destruction efficiency, meeting stringent emission standards.

- Energy Efficiency: The regenerative heat recovery system can recover up to 95% of the heat, significantly reducing energy consumption.

- Low Operating Costs: Due to high heat recovery, RTOs have lower operating costs compared to other thermal oxidizers.

- Versatility: RTOs can handle a wide range of exhaust volumes and concentrations, making them suitable for various industries.

- Reliability and Longevity: With proper maintenance, RTOs can operate reliably for many years, providing long-term benefits.

- Compact Design: RTOs are relatively compact, making them easy to integrate into existing facilities.

Applications in China

RTOs are widely used in various industries in China, including:

Printing Industry:

- Emissions Characteristics: Large volume, low concentration of VOCs.

Sources: Printing ovens, composite machine ovens, printing workshops, ink mixing rooms. - Pollutants: Acetate esters, n-propyl acetate, methyl ethyl ketone, isopropyl alcohol, ethanol, propylene glycol methyl ether acetate.

- Case Study: A large printing company in China successfully reduced VOC emissions by 99% using RTO technology, significantly improving air quality and complying with local regulations.

Chemical Industry:

- Emissions Characteristics: High concentration, complex composition.

- Sources: Reactors, storage tanks, transfer pipelines.

- Pollutants: Benzene, toluene, xylene, etc.

- Case Study: A chemical plant in China implemented RTO systems, achieving efficient VOC removal and substantial energy savings.

Pharmaceutical Industry:

- Emissions Characteristics: Small volume, high concentration.

- Sources: Solvent evaporation during production processes.

- Pollutants: Ethanol, acetone, ethyl acetate, etc.

- Case Study: A pharmaceutical company in China effectively controlled solvent emissions using RTO, ensuring compliance with strict environmental standards.

Automotive Industry:

- Emissions Characteristics: Moderate volume, moderate concentration.

- Sources: Paint booths, curing ovens.

- Pollutants: Solvents and VOCs from paints and coatings.

- Case Study: An automotive manufacturing plant in China significantly reduced VOC emissions from painting lines, enhancing overall production efficiency and environmental performance.

Regulatory Landscape in China

China has implemented a series of stringent environmental regulations to combat air pollution. Key regulations include:

- Air Pollution Prevention and Control Law: This law sets out the framework for air pollution control, including emission standards and monitoring requirements.

- VOC Emission Standards: Specific standards for VOC emissions in various industries, such as the “Standard for Emission of Volatile Organic Compounds from Coating and Ink Industries” (GB 37822-2019).

- Environmental Protection Tax Law: This law imposes taxes on pollutants, including VOCs, encouraging industries to adopt cleaner technologies like RTOs.

Economic and Environmental Benefits

Economic Benefits:

- Reduced Operating Costs: High heat recovery reduces energy consumption, leading to lower operating costs.

- Increased Production Efficiency: Reliable and continuous operation ensures minimal downtime, improving overall production efficiency.

- Extended Equipment Lifespan: Regular maintenance and optimized design extend the lifespan of the RTO system.

Environmental Benefits:

- Reduced Emissions: Highly efficient destruction of VOCs and other pollutants improves air quality.

- Sustainability: RTOs contribute to sustainable development by reducing carbon footprints and promoting green production.

- Compliance with Regulations: Meeting and exceeding environmental regulations enhances corporate social responsibility and public image.

Conclusion

Regenerative Thermal Oxidizers (RTOs) play a crucial role in China’s efforts to control air pollution and improve environmental quality. Their high efficiency, energy savings, and versatility make them an ideal solution for various industries. As China continues to prioritize environmental protection, the adoption of RTOs is expected to grow, contributing to a cleaner and more sustainable future.

By embracing RTO technology, Chinese industries can not only meet stringent environmental regulations but also achieve significant economic and environmental benefits, paving the way for a greener and more prosperous future.