China’s Best Regenerative Thermal Oxidizer for Waste Gas

Our Regenerative Thermal Oxidizer (RTO) is the ideal solution for industrial air purification, efficiently treating organic waste gases, reducing emissions, and operating costs.

Introduction to the Product

The RTO is a state-of-the-art environmental solution designed to reduce heat emissions during exhaust gas treatment. With an impressive thermal efficiency of about 98%, it ensures efficient and safe operation while having low operating costs. The RTO is particularly effective for large volumes of low-concentration exhaust gases with VOC concentrations below 5Nm3/h and zeolite runner concentration support exceeding 100,000 square hours.

Our RTO uses regenerative heat exchange devices for rapid heating and energy-saving effects. With graded combustion technology, it provides optimal effects and environmental protection. The uniform combustion chamber temperature allows for complete organic oxide decomposition. Our PLC-based automatic combustion control system ensures stable operation, and our heat energy recovery device enables efficient energy reuse. Additionally, our efficient switch valve design prolongs the working life of the RTO.

Processing Objects

The RTO is ideal for a wide range of chemical plants, treating exhaust gases from reactors, centrifuges, dryers, coating operations, and pharmaceutical manufacturing processes.

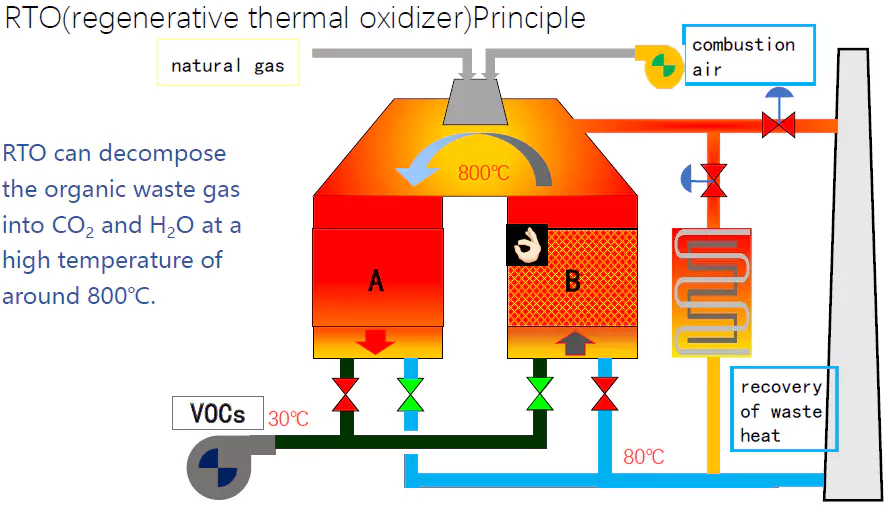

Flow Chart

Our RTO efficiently treats organic waste gases by reducing emissions and operating costs. The following flow chart illustrates the process:

Other Industrial Products

In addition to our RTO, we also supply various industrial products such as agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We are committed to providing high-quality products, preferential prices, and thoughtful services. Customers are welcome to customize with drawings and samples.

Frequently Asked Questions

1. What is a Regenerative Thermal Oxidizer?

A Regenerative Thermal Oxidizer (RTO) is a cutting-edge environmental solution designed to reduce heat emissions during exhaust gas treatment. It is ideal for a wide range of chemical plants, treating exhaust gases from reactors, centrifuges, dryers, coating operations, and pharmaceutical manufacturing processes.

2. What are the technical advantages of the RTO?

Our RTO uses regenerative heat exchange devices for rapid heating and energy-saving effects. With graded combustion technology, it provides optimal effects and environmental protection. The uniform combustion chamber temperature allows for complete organic oxide decomposition, and our efficient switch valve design prolongs the working life of the RTO.

3. What are the processing objects for the RTO?

The RTO is particularly effective for large volumes of low-concentration exhaust gases with VOC concentrations below 5Nm3/h and zeolite runner concentration support exceeding 100,000 square hours. It is ideal for treating exhaust gases from reactors, centrifuges, dryers, coating operations, and pharmaceutical manufacturing processes.

4. How does the RTO reduce emissions and operating costs?

Our RTO efficiently treats organic waste gases, reducing emissions and operating costs. It uses regenerative heat exchange devices for rapid heating and energy-saving effects, and its uniform combustion chamber temperature allows for complete organic oxide decomposition. Additionally, our heat energy recovery device enables efficient energy reuse.

5. What other industrial products does your company supply?

In addition to our RTO, we also supply various industrial products such as agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more.

Regenerative Thermal Oxidizer: Performance Characteristics and Types

Regenerative Thermal Oxidizer (RTO) is a type of industrial air pollution control system that is designed to remove hazardous gases and particulate matter from industrial exhaust streams. RTOs are highly efficient, cost-effective, reliable, and environmentally friendly. The performance characteristics of RTO can be summarized as follows:

- High Destruction Efficiency: RTOs can achieve up to 99% destruction efficiency for volatile organic compounds, hazardous air pollutants, and other air pollutants.

- Low Operating Cost: RTOs use a regenerative process to operate, which means that the heat generated during the combustion process is recycled and used to preheat the incoming exhaust gas stream. This results in low operating cost and high energy efficiency.

- Flexible Operation: RTOs can operate over a wide range of gas flow rates and pollutant concentrations, making them suitable for various industrial applications.

- Minimal Maintenance: RTOs are designed for long-term operation with minimal maintenance requirements. They have no moving parts and require only periodic cleaning and inspection.

There are different types of RTOs, including three-bed RTOs, two-bed RTOs, and single-bed RTOs. The types of RTOs are classified based on the number of beds, flow control mechanisms, and heat recovery systems. The characteristics of each type of RTO are as follows:

- Three-Bed RTO: This type of RTO has three beds of ceramic heat exchange media. It provides the highest level of heat recovery and energy efficiency. Three-bed RTOs are ideal for applications with high gas flow rates and low pollutant concentrations.

- Two-Bed RTO: This type of RTO uses two beds of ceramic heat exchange media. It is more compact than three-bed RTOs and requires less space. Two-bed RTOs are suitable for applications with moderate gas flow rates and pollutant concentrations.

- Single-Bed RTO: This type of RTO has only one bed of ceramic heat exchange media. It is the simplest and most economical type of RTO. Single-bed RTOs are suitable for applications with low gas flow rates and high pollutant concentrations.

Advantages of Regenerative Thermal Oxidizer Made of Different Materials

The materials used to construct RTOs are an important factor in their performance and longevity. The advantages of RTOs made of different materials are as follows:

- Ceramic RTOs: Ceramic RTOs are the most commonly used type of RTO. They are durable, resistant to thermal shock, and can withstand high temperatures. Ceramic RTOs have a long lifespan and require minimal maintenance.

- Carbon Steel RTOs: Carbon steel RTOs are cost-effective and suitable for low to moderate temperature applications. They are prone to corrosion and require regular maintenance.

- Stainless Steel RTOs: Stainless steel RTOs are highly resistant to corrosion and can withstand high temperatures. They are more expensive than carbon steel RTOs but have a longer lifespan and require less maintenance.

- Composite RTOs: Composite RTOs are made of a combination of materials, such as ceramic and metal. They offer a balance between durability, cost-effectiveness, and thermal efficiency.

Future Development Trends and Opportunities of Regenerative Thermal Oxidizer

The demand for RTOs is expected to increase in the coming years due to the growing concern for environmental protection and the implementation of strict emission regulations. The future development trends and opportunities of RTOs can be summarized as follows:

- Innovative Designs: Manufacturers are developing innovative designs to improve RTO performance and efficiency, such as the use of heat exchangers, regenerative catalysts, and variable frequency drives.

- Integration with Other Technologies: RTOs can be integrated with other technologies, such as thermal oxidizers and catalytic oxidizers, to provide a more comprehensive air pollution control solution.

- Expansion into Emerging Markets: The demand for RTOs is growing in emerging markets, such as Asia-Pacific and Latin America, due to the increasing industrialization and urbanization in these regions.

How to Choose a Suitable Regenerative Thermal Oxidizer

Choosing a suitable RTO requires careful consideration of several factors, including emissions characteristics, energy efficiency and heat recovery, regulatory compliance, operational and maintenance considerations, and system size and cost considerations.

- Emissions Characteristics: The RTO should be designed to handle the specific type and concentration of pollutants emitted by the industrial process.

- Energy Efficiency and Heat Recovery: The RTO should be designed to maximize energy efficiency and heat recovery to minimize operating costs.

- Regulatory Compliance: The RTO should comply with local and federal air pollution control regulations and standards.

- Operational and Maintenance Considerations: The RTO should be easy to operate and maintain, with minimal downtime and maintenance requirements.

- System Size and Cost Considerations: The RTO should be sized appropriately for the industrial process and should be cost-effective in terms of capital and operating costs.

Conclusion

In summary, Regenerative Thermal Oxidizer is a highly efficient and cost-effective air pollution control system that is widely used in various industrial applications. The performance characteristics and types of RTO were discussed, along with the advantages of RTOs made of different materials. The future development trends and opportunities of RTOs were analyzed, and the factors to consider when choosing a suitable RTO were outlined. By selecting the appropriate RTO, industrial processes can minimize their environmental impact and comply with air pollution control regulations.

Author: Dream

All the content of the page is from the Internet, the content is only as a reference for product selection, our products are replacement parts and not original spare parts; we are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts, our replacement parts can be perfectly adapted to the original spare parts; if you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.